MOU between GENETEC & APCS. Who's Energy Absolute (EA)? The first Gigafactory in ASEAN

Genetec A baby step

Publish date: Wed, 13 Apr 2022, 07:32 PM

https://klse1.i3investor.com/servlets/anpth/1658916.jsp

| Type | Announcement |

| Subject | MEMORANDUM OF UNDERSTANDING |

| Description |

GENETEC TECHNOLOGY BERHAD ("Genetec" or "the Company")

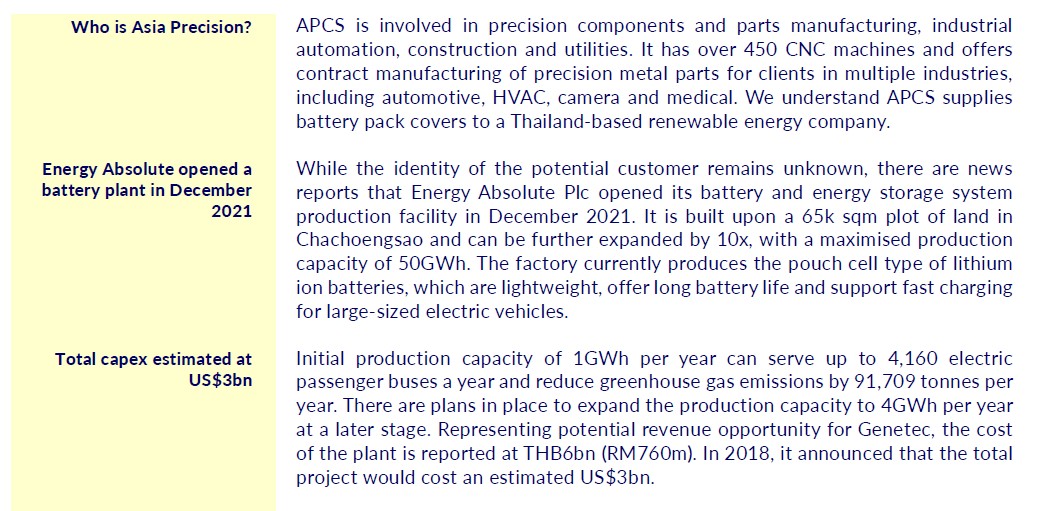

- Memorandum of Understanding ("MOU") between Genetec and Asia Precision Public Company Limited

|

|

The Board of Directors of Genetec wishes to announce that the Company had on 11 January 2022 entered into a MOU with Asia Precision Public Company Limited to jointly collaborate and cooperate to carry out the Project as stated therein the MOU.

Please refer to the attached file for the full text of the announcement.

This announcement is dated 11 January 2022. |

|

https://www.bangkokpost.com/business/2230683/new-battery-plant-crucial-for-ev-work

New battery plant 'crucial' for EV work

PUBLISHED : 12 DEC 2021 AT 20:04

The SET-listed Energy Absolute Plc (EA) on Sunday opened its battery and energy storage system (ESS) production facility, which is said to have the largest production capacity in Asean.

Built on about 90-rai plot of land in Chachoengsao in the Eastern Economic Corridor (EEC), the lithium-ion battery-making facility can be further expanded by 10 times. Its production capacity can likewise be maximised to 50-gigawatt hours per year (GWh/year), the largest of its kind in Asean, said a source.

The battery factory, operated by EA’s subsidiary Amita Technology (Thailand) Co, is located in a zone prepared for accommodating further investments in related businesses in the country’s new S-curve industries.

The factory will play a crucial role in electric vehicle production, measures related to renewable energy adoption and efforts to curb the emission of greenhouse gasses, said Somphote Ahunai, chief executive of EA.

The factory is flexibly designed and allows for future upgrades and adjustments to production procedures to accommodate for developments in battery technology, Mr Somphote said.

It now produces the pouch cell type of lithium-ion batteries, which are lightweight yet offer a long battery life and support fast charging for large-sized electric vehicles, he said.

A fast charge can be completed within 15 minutes, which makes it suitable for use with large commercial electric vehicles, including electric cars, trucks, passenger buses and passenger boats, he said.

A 1GW lithium-ion battery, for instance, may power an electric passenger bus to run up to 240 kilometres per charge, he said, adding that with the factory’s initial production capacity it can serve up to 4,160 such electric passengers buses a year.

With 4,160 electric passenger busses running on power supplied by lithium-ion batteries, it is estimated that greenhouse gas emissions will be cut by 91,709 tonnes per year, he said.

Aside from its lithium-ion battery production technology, the factory is also equipped with an expanded supply chain and has its own recycling facility, he said.

Industry Minister Suriya Jungrungreangkit on Sunday presided over the factory’s opening ceremony.

Related Stocks

| Chart | Stock Name | Last | Change | Volume |

|---|

Market Buzz

More articles on Genetec - A baby step

Created by Genetec A baby step | Apr 24, 2024

Created by Genetec A baby step | Feb 29, 2024

Created by Genetec A baby step | Jan 18, 2024

Created by Genetec A baby step | Jan 04, 2024

Created by Genetec A baby step | Dec 12, 2023