A recently-inked agreement may turn out to be a positive development for HLT Global Bhd.

HLT, which is involved in the design, installation, testing and commissioning of glove-dipping lines, aside from being a glove manufacturer, says the technology, which will soon be marketed to other glove manufacturers, can boost production output by 30% to 50%.

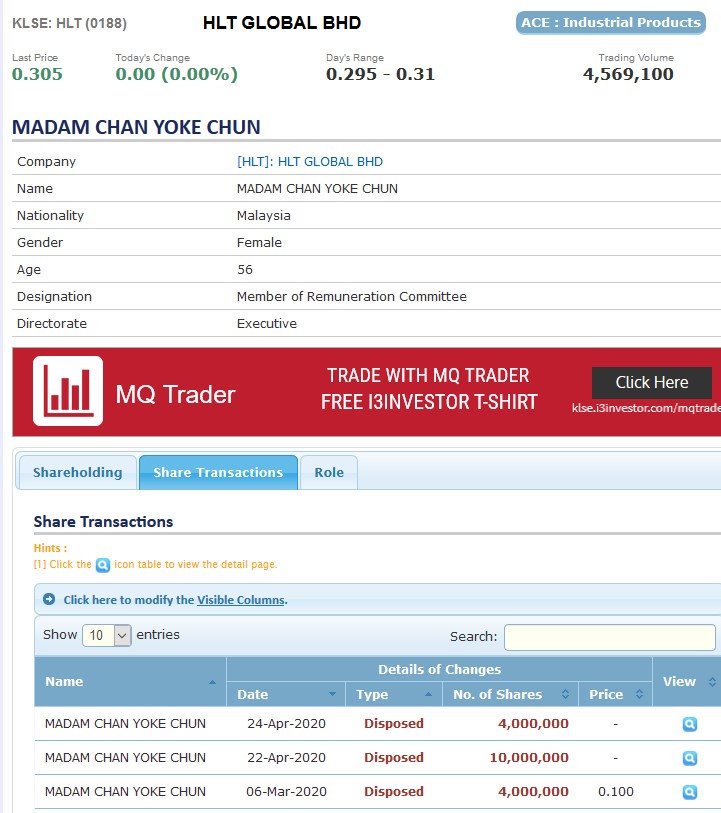

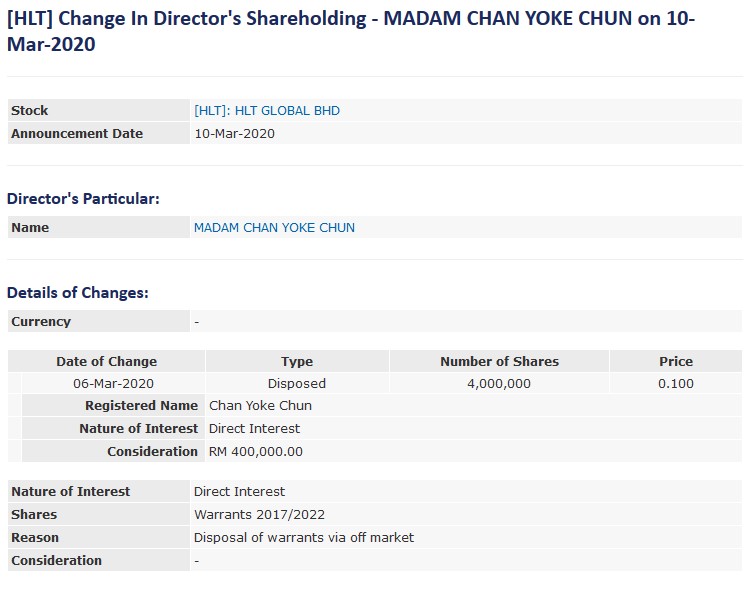

HLT Global’s group MD Chan Yoke Chun says the patent licence agreement it entered into last month gives HLT Global exclusive worldwide rights for the technology.

Via the agreement, she says, HLT’s unit, HL Advance, will likely be the first glove-dipping line maker to introduce the high-density triple former assembly to the market, which is the latest in rubber glove manufacturing technology.

It expects to achieve commercialisation of the line within the next six to 12 months.

This comes at a time when glovemakers across the globe are ramping up production to keep up with surging demand, as the number of Covid-19 cases spike, and with the recent declaration of the disease as a pandemic. Currently, Chan notes, most glove manufacturers are using what is known as the double former assembly technology.

“We are envisaging the repeat of history in the rubber glove industry as seen during the transformation from the single former holder assembly to the current double former assembly.

“Given that the patent applications are filed in major glove-producing countries such as Malaysia, Indonesia, Thailand and China, we anticipate that upon achieving commercial and technical viability, any glove manufacturers that are interested in adopting the technology would need to work with us - directly or indirectly, ” she says.

Since announcing the agreement last month, she says, the group has already been receiving enquiries from glove manufacturers expressing interest in the technology.

Chan says rubber glove manufacturers will have the option of either building a brand new line or upgrading their existing glove dipping lines from double to triple former assembly.

An upgrade from double to triple former glove dipping line, she says, would save the glove manufacturers from incurring substantial capital expenditure costs such as purchase of land and construction of buildings.With the adoption of the technology, she adds, operational costs such as energy costs could potentially be reduced by 20% to 30%, while also lowering total capital expenditure for new investments by 20% to 30%.

HLT Global, which commenced its operations about a decade ago, has two core business segments, with its glove-dipping lines segment, contributing about 37% of its revenue, and its rubber gloves segment accounting for some 63% of revenue.

It currently markets its products locally, as well as to other markets including Thailand, Indonesia, Vietnam, China, India and Saudi Arabia.

Based on Bloomberg data, HLT global has a market capitalisation of RM94.7mil and a price earnings ratio of 20.33 times.

On Friday, its share price closed at 18.5 sen.

In terms of earnings, the group posted a net profit of RM4.68mil for the financial year ended Dec 31,2019, recovering from a net loss of RM26.1mil in the previous year.

Its revenue for the period was RM144.4mil, also up from RM128.78 previously.

As for the most recent fourth quarter, the group narrowed its net loss to RM2.2mil from a net loss of RM19.8mil during the same period a year earlier.

Back to its latest deal, HLT Global’s unit entered into a Patent License Agreement last month, whereby, HL Advance Technologies (M) Sdn Bhd was granted exclusive rights for the technology in connection with its glove dipping machine manufacturing business, fabrication works on metal and stainless steel products and carrying out all supporting services, for a period of three years with a further automatic extension of two years.

As the next step in its plans, Chan says the group is planning to develop a prototype glove-dipping line using the technology - to test its commercial and technical viability - at its own glove plant.

“Our current financial resources are sufficient for us to invest in the R&D of this latest technology, ” she says, declining to reveal the investment amount.

Explaining how the technology works, Chan says the high density triple former holder assembly is an expansion from the current double former holder assembly, whereby a special holder is designed to create space between the original double holder to prevent touching or knocking.

A third holder is then slotted in the empty space between two double former holders.

This, she says, will allow additional gloves placed in the third holder to be put through the curing process.

“The additional holder will increase the production capacity of a double former dipping line by 30% to 50% without changing much of its configuration, or the energy consumption, ” she says.

As the group is still in the midst of research and development, she says the development is not expected to have a significant impact of HLT Global’s earnings for the current financial year. “However, we are confident that this will contribute positively to future earnings, ” Chan says.

The group is targeting rubber glove manufacturers across the globe as potential customers for the technology, and believes that its return to profitability in the recent quarter will be sustainable, based on its current orders in hand as well as prospects ahead.