How to make iron and steel? Koon Yew Yin

Koon Yew Yin

Publish date: Wed, 09 Nov 2022, 03:22 PM

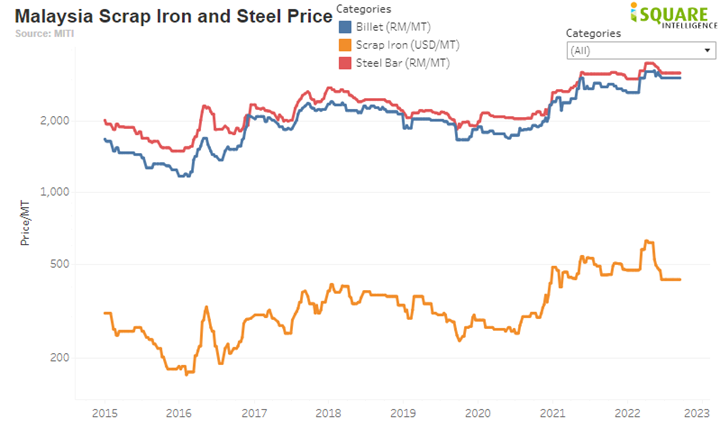

After the Covid 19 pandemic lockdown, there is more construction activities in Malaysia. The demand for steel is increasing. As a result, steel price has been increasing as shown on the charts below.

All steel products manufacturers namely AYS, Leon Fuat and others should report higher profits in the next few quarters.

One of the subjects I studied in my Civil Engineering course was metallurgy which include iron, steel and many other alloys. Steel is widely used in the constructions of reinforced concrete buildings, bridges, infrastructures and many other structures. Steel is also used for the construction of factory buildings. Steel comes from iron.

What is Iron and how it is made? Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite, hematite, goethite, limonite or siderite.

Iron is a metallic element (periodic table symbol: Fe) with a melting point of 1150 degrees Celsius upwards.

It is the fourth most widely distributed element on the earth’s crust but is found as iron ore rather than as a useable metal. Iron ore comes in a variety of forms and looks like rock. It is a mixture of iron, oxygen and other elements, mixed in with sands and clays. To make a useable metal, an ironworks has to get rid of the unwanted components of this mixture and keep as much of the iron as possible, producing a purer metal.

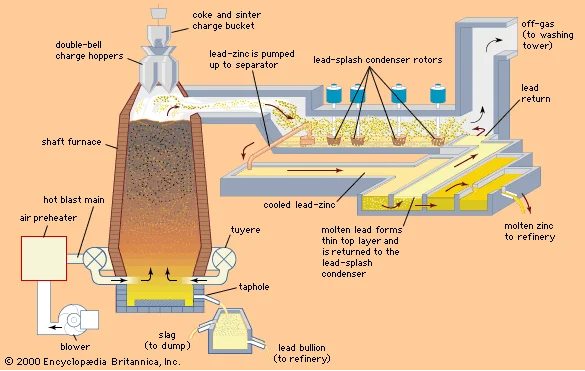

What is a blast furnace? A blast furnace, a vertical shaft furnace that produces liquid metals by the reaction of a flow of air introduced under pressure into the bottom of the furnace with a mixture of metallic ore, coke, and flux fed into the top. It is used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper.

What is steel and how it is made?

Steel is one of the world’s most versatile materials. Defined as an alloy of iron and carbon, it’s both strong and durable. Furthermore, over two-thirds of all steel produced in North America is recycled annually, according to the American Iron and Steel Institute. To make steel, however, metalworking companies must perform several steps involving the use of raw iron.

All steel is made using raw iron. As previously mentioned, steel is characterized by the presence of iron and carbon. The ratio of these two elements varies depending on the specific type of steel being made. With that said, most types of steel contain about 1% carbon and 97% iron, with the remaining 2% consisting of trace elements and impurities.

The amount of carbon will affect the steel’s physical properties. Generally speaking, the greater the concentration of carbon, the stronger and harder the steel is. With that said, adding too much carbon to steel can make it susceptible to rust and corrosion while also making it difficult to weld and form.

Smelting Raw Iron

Whether it’s low-carbon, medium-carbon or high-carbon, the first step to producing steel involves smelting raw iron. After the iron ore has been mined and harvested, it’s smelted in a large furnace. It’s not uncommon for these furnaces to achieve temperatures of over 3,000 degrees Fahrenheit. As the iron heats up and liquefies, it separates from its impurities, thereby creating cleaner iron that’s better suited for the production of steel.

Adding Carbon

When smelting raw iron with the goal of producing steel, metalworking companies will also use this opportunity to add carbon. Carbon, of course, is essential to the process. It distinguishes steel from raw iron, resulting in greater strength and durability. As the raw iron turns from solid to liquid, a specific amount of carbon is added.

Adding Limestone

In addition to carbon, metalworking companies will also feed limestone into the furnace when producing steel. Both carbon and limestone are essential to the steel-making process. Limestone is used to remove impurities, including flux, by helping the iron separate from the impurities.

In the past, producing steel was a painstakingly tedious and difficult — as well as dangerous — process. Thanks to recent advancements in the field of metalworking, though, companies can produce significantly more steel in less time. A typical blast furnace can convert nearly 400 tons of iron and carbon into steel in just 40 minutes. Hearth furnaces can produce similar volumes of steel but require a greater length of time.

What is cast iron?

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing.

What is stainless steel and how it is made?

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's resistance to corrosion results from the chromium, which forms a passive film

How to increase the tensile strength of steel?

The most common method of increasing a steels tensile strength is through a process called heat treating. In this process the base metal is brought to a temperature at or above its anneal point and held until all previous thermal history has been removed. At this point the metal is then quenched (a very rapid drop in temperature) by one of several methods. One method is an air quench, where a very high volume of air is directed at both faces of the metal causing the surface to go into compression while the core (center) stays in tension. The amount of air and the application time will determine the degree (and depth) of the heat treatment. Oils are often substituted for the air and this method, while achieving the same results, will also impart other characteristics to the metal from the chemical reaction of the oil/metal interface. There are many chemical treatments that can be used to increase tensile strength, I have only presented two here. There are books about heat treating and tempering and general metallurgy that go into great depth on this subject.

Related Stocks

| Chart | Stock Name | Last | Change | Volume |

|---|

More articles on Koon Yew Yin's Blog

Created by Koon Yew Yin | Nov 21, 2024

Indonesia is the biggest palm oil producer in the world. Indonesia plans to implement biodiesel with a mandatory 40% blend of palm oil-based fuel from Jan. 1 next year, a senior energy ministry offici

Created by Koon Yew Yin | Nov 20, 2024

Indonesia plans to implement biodiesel with a mandatory 40% blend of palm oil-based fuel from Jan. 1 next year, a senior energy ministry official said recently, lifting prices of the vegetable oil...

Created by Koon Yew Yin | Oct 30, 2024

Latest poll on 30th Oct 2024

Created by Koon Yew Yin | Oct 30, 2024

Latest poll on 30th Oct 2024

Created by Koon Yew Yin | Oct 25, 2024

The group is expected to deliver better profits and revenue from its pipe coating, engineering, and bioenergy segments.

Created by Koon Yew Yin | Oct 14, 2024

Today I read the article by Murray Hunter titled “A Visit to the Malaysian Communist Party tunnels in Betong, Thailand”, which is an important part of Malaysia’s history.

Created by Koon Yew Yin | Oct 04, 2024

KSL is still the cheapest based on a 4.4 PE ratio, which means its share price should continue to go up. Unfortunately, there are a few small investors who always queue to sell at cheaper prices...

Created by Koon Yew Yin | Oct 04, 2024

KSL is still the cheapest based on a 4.4 PE ratio, which means its share price should continue to go up. Unfortunately, there are a few small investors who always queue to sell at cheaper prices...

Created by Koon Yew Yin | Sep 06, 2024

Water pollution is a huge challenge for freshwater in the UK, impacting our rivers, streams, and lakes and the wildlife that call them home.

Created by Koon Yew Yin | Sep 03, 2024

State housing and local government committee chairman Datuk Mohd Jafni Md Shukor said demand for properties in Johor has gone up since last year’s announcement about the SEZ.