Bumi Armada Proposes Floating Carbon Storage and Injection Unit (FCSIU) for CO2 Capture Overcoming Existing Barriers

Robert Waters

Publish date: Sat, 21 Oct 2023, 05:42 PM

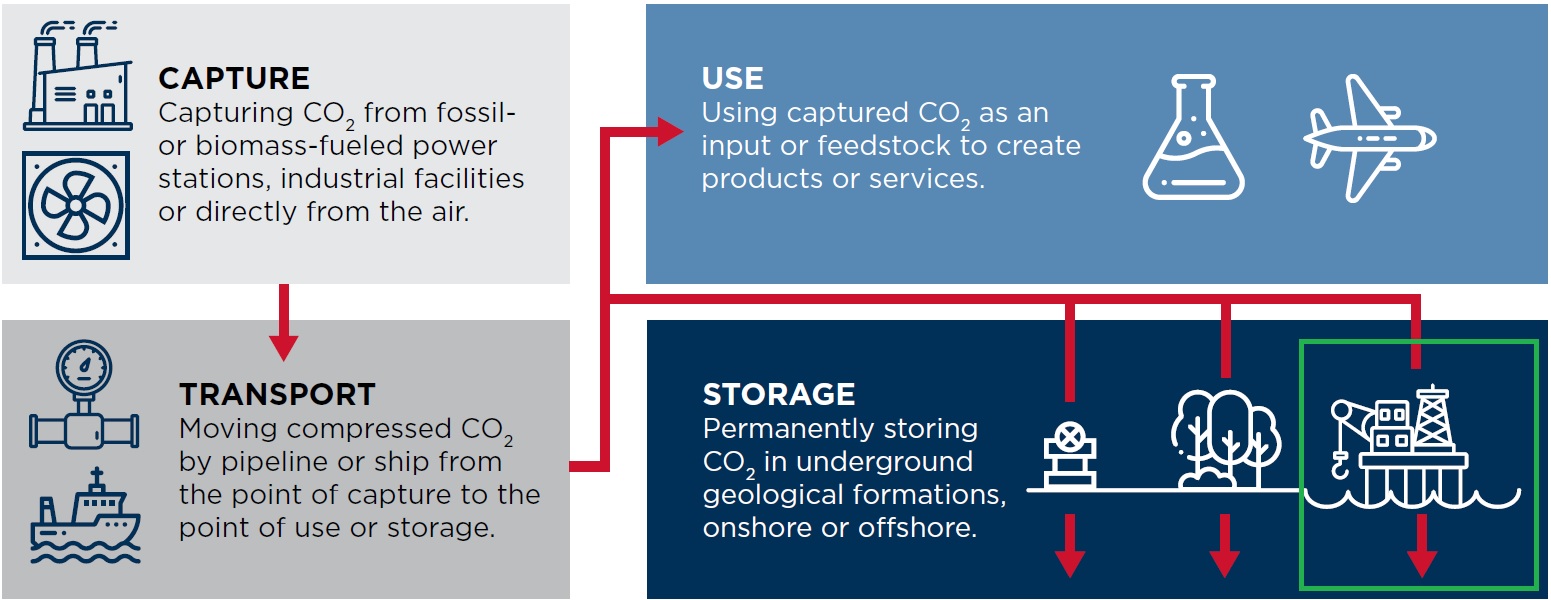

Malaysia’s offshore oilfield service company Bumi Armada Berhad is looking to build out its efforts for CO2 transport and storage by presenting its design for a floating LCO2 terminal. They were awarded an Approval in Principle from American Bureau of Shipping (ABS). Bumi Armada is a newcomer to this field. ABS has been promoting carbon capture for many years, and they even authored a white paper on it. Climate change is a serious issue and projected greenhouse gas (GHG) emissions present a serious concern for the environment soon. The Intergovernmental Panel on Climate Change (IPCC) presented scenarios for limiting global temperature rise to 1.5°C in their Special Report issued in 2019, including carbon capture systems. Carbon Capture, Utilization, and Storage (CCUS) is the process by which CO2 can be captured, cleaned, dehydrated, liquefied, transported, and stored or utilized at a final location (green box indicates Bumi Armada’s facility – FCSIU).

Figure 1 CCUS Value Chain

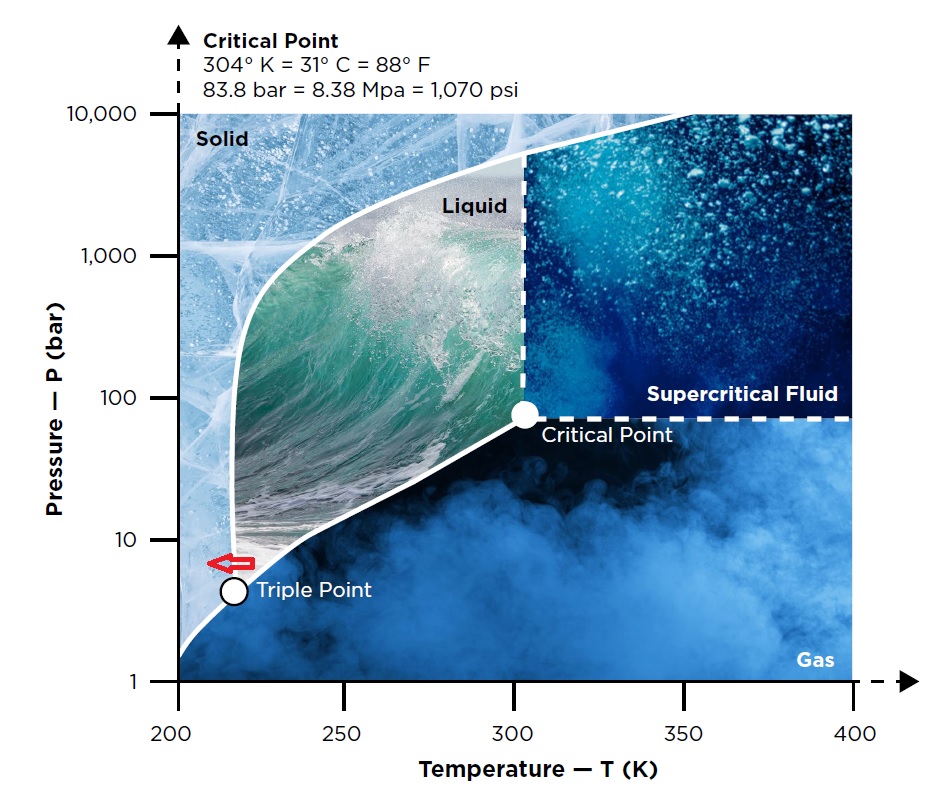

The CO2 stream goes through purification and liquefaction before transport. Liquefaction is an important aspect of CCUS that also consumes a lot of energy. CO2 can be liquified at various pressures between the triple point (0.518 MPa, −56.6°C) and critical point (7.38 MPa, 31.1°C). The liquefied CO2 at such temperature and pressure, can take approximately 1/500th of the volume of CO2 in gaseous form at standard temperature and pressure. When pressured above its critical temperature and critical pressure (8 MPa), the CO2 can be compressed to reach supercritical form that has a higher density and can avoid co-existence of two-phases. Red arrow shows conditions of CO2 during transportation (near triple point as we want lowest pressure and highest temperature), demonstrating how easily it can transform into solid (ice) during cooling or into gas during isothermal pressure drop.

Figure 2 CO2 Phase Diagram

Long-term storage of CO2 is accomplished by injection into natural porous rock formations such as depleted oil or gas reservoirs, coal beds, or saline aquifers. For many years, CO2 has been injected during hydrocarbon production as an enhanced oil recovery (EOR) method to stimulate additional returns from the well. The CO2 is offloaded to a buoy and flexible riser. The injection facility provides further conditioning, pressurization, and heating systems before pumping into the well can proceed. ABS states in their white paper that “ship-type production units like FPSOs would not be well suited for injection platforms since their large oil storage capacity is not useful with CO2 and the inspection and maintenance costs associated with the large hull structures would be high.” (YES!)

Same challenge applies the transport is that LCO2 is carried in cryogenic pressurized tanks. Current designs for the tanks are limited in size before the tanks become too heavy and too expensive, according to ABS.

Bumi Armada is not afraid to take on the challenges above. They came up with a novel solution. And in September 2023 ABS has awarded Approval in Principle (AiP) for Bumi Armada’s pioneering design for a Floating Carbon Storage and Injection Unit (FCSIU). The concept is a floating terminal capable of storing and injecting liquified carbon dioxide (LCO2) into depleted oil and gas fields or aquifers. As can be seen below, a battery of smaller tanks is constructed offboard in the seawater facilitating temperature control and solving problem of hull tank insufficient strength.

Figure 3 Bumi Armada (Approved in Principle) Carbon Storage and Injection Unit

ABS highlights the challenges in liquid carbon transport and storage. While there are currently over 100 gas carriers capable of carrying CO2, only a few pure LCO2 carriers exist in the world. As liquified CO2 is the most promising state (form) both for transport and injection for storage, it presents the challenges as well. Because CO2 is carried at around -54.4 Celsius and 5.7 bar pressure in a liquid state, it can rapidly change from the liquid state to the solid state when there is a drop in pressure. This leads to the formation of dry ice, causing technical and safety challenges. Obviously, pumping liquid with solids (or gas) would lead to damage. However, Bumi Armada and partners are willing to find solutions to all the technological problems based on their experience in offshore oil and gas.

More articles on Bumi Armada Berhad Attempts Recovery after Financial Catastrophes of the Past

Created by Robert Waters | Oct 06, 2023

Bumi Armada - world’s first FPSO with sulphur processing plant producing molten sulphur. Carbon Capture and Storage Similar. BUMI ARMADA BERHAD KLSE (MYR): ARMADA (5210). Technical info.

Created by Robert Waters | Sep 16, 2023

Bumi Armada attempts to venture into FLNG business by a new partneship in Indonesia Madura BD Field.

.png)