Bumi Armada's Role in Madura BD Field Development before Proposed FLNG

Robert Waters

Publish date: Sat, 16 Sep 2023, 03:08 PM

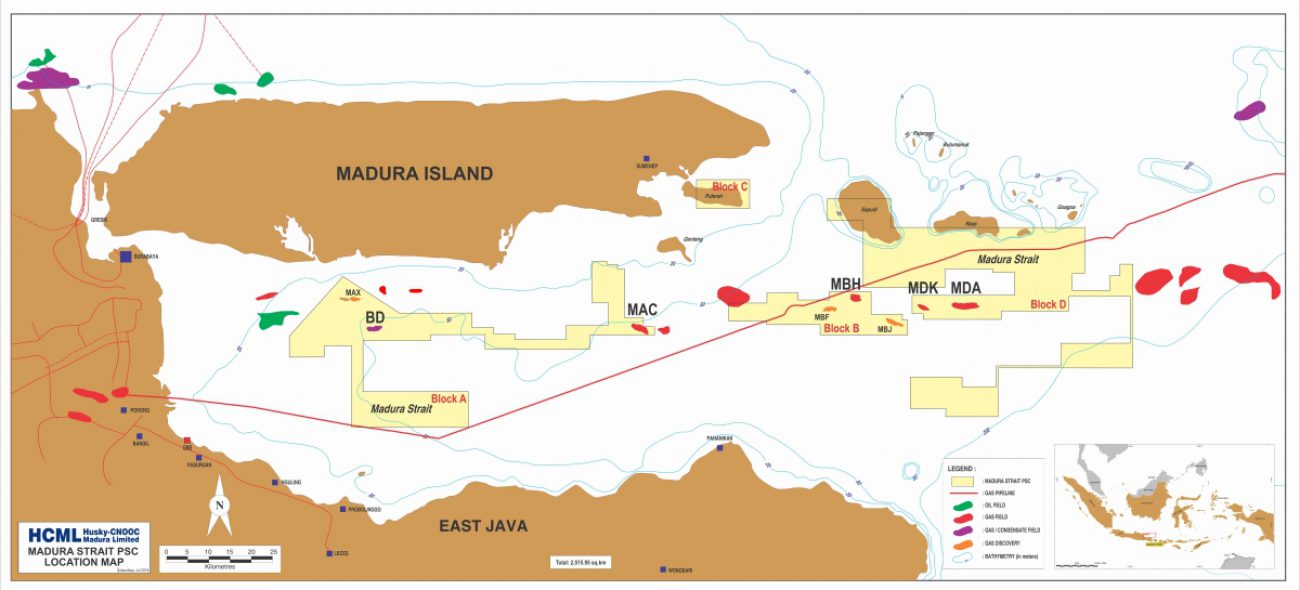

Bumi Armada Berhad signed a non-binding agreement with PT Pertamina International Shipping and PT Davenergy Mulia Perkasa (DMP), an Indonesian natural gas trading company, for the development and commercialisation of liquefied natural gas (LNG) from the Madura gas field in Indonesia. The collaboration aims to design, engineer, construct, install, commission, hook up and operate the Floating Liquefied Natural Gas (FLNG) facility compatible with LNG carriers. The parties also intend to transport LNG to consumers located in areas that lack access to clean energy sources. Preliminary discussions have been initiated with several potential off-taker clients and the first shipment of LNG is anticipated to take place three years after making the final investment decision. Bumi Armada is already active in this area. Existing project is described below.

Madura BD field, which was discovered in 1988 is located approximately 65 km East of Surabaya and 16 km South of Madura Island contains reserves of 422 BCF (billion cubic feet) of natural gas and 18.7 MMBBL (million barrels) of condensate. The development project of Madura BD field produces approximately 100 MMSCFD (million standard cubic feet per day) of gas and 6,000 BCPD (barrels condensate per day). The produced gas is transferred to the domestic contracted customers and the condensate is shipped by shuttle tankers to domestic users and regional users in South East Asia.

The project includes installation of a well-head platform (WHP) at a water depth of 55 meter; construction of a floating production, storage and offloading (FPSO) vessel; construction of a gas metering station (GMS) onshore; installation of two flexible risers between the WHP and FPSO; and construction of a 52 km long pipeline to export gas to the GMS. On 12 October 2015, the jacket was installed at the site. After WHP installation was completed, the drilling job for four wells and two slots for future development took place.

Well Head Platform (WHD)

The next work was 52-km pipe-laying, consisting of two sections: onshore and offshore. The work was initiated by trenching for both onshore and offshore pipeline. The offshore pipes were concrete-coated first to prevent corrosion and then loaded onto a barge. Floating foam was applied to the offshore pipeline to support offshore pipe laying and pulling process. The onshore pipeline, equipped with floating drums, was pulled to the shore to be connected to the offshore pipeline.

The FPSO named Karapan Armada Sterling III (KAS III) was constructed in the shipyard of Keppel Offshore & Marine in Singapore. KAS III FPSO arrived at the location of BD field on 13 January 2017. Two flexible riser hoses of 10 inch and 16 inch in diameter, connecting the WHP and FPSO were installed. The BD WHP operation was commissioned. All equipment and components were tested and checked.

Karapan Armada Sterling III (KAS III)

Sour gas with around 4500 ppm of H2S and condensate produced from the BD field is transferred from Wellhead Platform to FPSO KAS III, which is the world’s largest H2S processing offshore floating facility. Topside facilities can process 110 MMSCFD sales gas, 7500 BOPD condensate and recover 20 T of sulphur per day. Sweet gas is sold to gas buyer via the onshore Gas Metering Station (GMS), byproduct of acid gas is converted into molten sulphur on the FPSO and offloaded, condensate is also periodically offloaded to a shuttle tanker. The operation is controlled from a control room. Maintenance activities are regularly carried out. Facility is provided with a health clinic and other supporting safety equipment. For personnel mobilization from FPSO to BD WHP, a lifting basket is used.

BUMI ARMADA BERHAD

KLSE (MYR): ARMADA (5210)

Related Stocks

| Chart | Stock Name | Last | Change | Volume |

|---|

More articles on Bumi Armada Berhad Attempts Recovery after Financial Catastrophes of the Past

Created by Robert Waters | Oct 06, 2023

Bumi Armada - world’s first FPSO with sulphur processing plant producing molten sulphur. Carbon Capture and Storage Similar. BUMI ARMADA BERHAD KLSE (MYR): ARMADA (5210). Technical info.

Felix888

Good sharing Robert! Thank you!

2023-09-17 17:38